The dry coal preparation technology, which is highly valued by the state, can be expected in the future

- Update: 2021-05-31 Views: 388

- In 2020, China's coal output will be 3.9 billion tons, and the energy consumption pattern dominated by coal will not be changed for a long time. China's coal resource endowment is poor, and the reserves of low-quality coal are large, accounting for about 40%. The ultra-low ash coal with ash content less than 10% accounts for only 15% - 20% of the retained reserves, and the medium and high sulfur coal with sulfur content greater than 1% accounts for 33% of the total.

75% of China's coal is used for direct combustion. The average ash content of power coal is 28.6%, the average sulfur content is 1.01%, and the average ash content is 15.5% and the average sulfur content is 0.66%; Coal has made great contributions to the development of national economy, but also brought serious environmental pollution.

Coal preparation can effectively remove ash, sulfur and other impurities in coal, improve quality, promote clean utilization of coal, and play an important role in reducing air pollution. Burning coal after sorting and upgrading can improve coal-fired efficiency by 10-15% and save railway transportation capacity by 18%; For every 100 million tons of raw coal selected, 16 million tons of gangue, 1.3 million tons of pyrite sulfur and 440000 tons of sulfur dioxide emission can be reduced.

Shanxi, Shaanxi, Inner Mongolia, Xinjiang and other coal producing provinces are mostly dry and lack of water. In addition, lignite, long flame coal and other coals with large reserves and gangue in some coals are very easy to be slimed when exposed to water. If wet washing process is used to process them, it is necessary to build a huge slime water treatment system, which will not only produce a large number of slimes with low calorific value and difficult to sell, but also have high construction investment and complex system maintenance, As a result, the operating costs of enterprises remain high. In addition, every winter, coal mines in Northeast and Northwest China also need to invest a lot of money to solve the problems of product loading, storage, freezing warehouse and so on. Therefore, the coal preparation industry urgently needs high-efficiency dry coal preparation technology.

Dry coal preparation in China can be divided into the following three stages:

No.1 phase I

In the 1980s and 1990s, the exploration and research stage of air dense medium and composite dry coal preparation began.

No.2 phase II

At the beginning of the 21st century, we focused on the technical problems encountered in the engineering of dry coal preparation, such as accuracy, efficiency, reliability and adaptability.

No.3 phase III

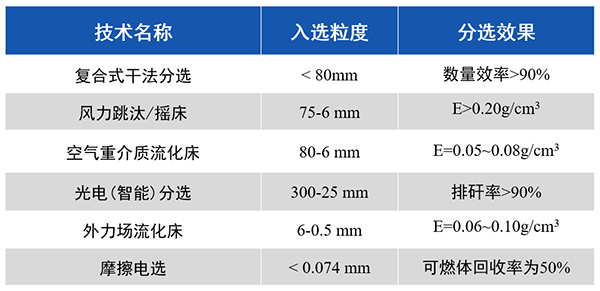

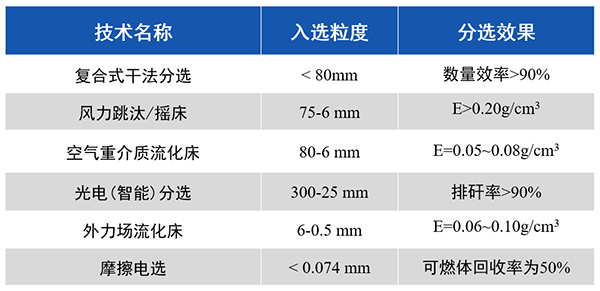

In recent ten years, China has made rapid development in large-scale composite dry separator, gas-solid fluidization dry separation theory, new generation dry heavy medium fluidized bed separator, wind jig and shaker separator, modular high-efficiency dry coal preparation process system, photoelectric (intelligent) dry separator and so on.

In 2016, the action plan for energy technology revolution and innovation issued by the national development and Reform Commission and the energy administration included "high efficiency dry coal preparation technology" in the key innovation action line of energy technology revolution. "Dry coal preparation technology", "ultra clean coal separation", "high efficiency ash reduction and desulfurization" and other coal separation and processing technologies were listed in the global engineering frontier in 2018 and 2019. The action plan for energy technology revolution and innovation (2016-2030) proposes to "form a complete clean and efficient coal utilization technology system and reach the world leading level as a whole". In 2017, China Coal Industry Association established the Research Center for dry coal preparation engineering in the coal industry. In 2019, the 2019 national dry coal preparation site meeting hosted by China Coal Industry Association and China coal processing and Utilization Association and undertaken by Tangshan Shenzhou Machinery Group Co., Ltd. was held. In 2020, China coal processing and Utilization Association approved the release of the group standard of technical specification for dry coal preparation.

Many countries along the "the Belt and Road" initiative are rich in coal resources and short of water resources, providing opportunities for the development of efficient dry coal preparation technology and broad application prospects.

With the unremitting efforts of generations of coal preparation personnel, China's dry coal preparation technology has made a major breakthrough and the technical level is internationally leading. With the support of relevant national policies, enterprises, universities and scientific research institutes have made joint efforts to strengthen the combination of industry, University and research. The application of dry coal preparation technology has entered a stage of rapid development.

PREX:NONE

NEXT:NONE